Electric vehicle manufacturers are increasingly looking beyond traditional pack structures to meet the demands of new technology. LEAD Intelligent is at the forefront of this movement, providing innovative solutions for cell to pack battery production that manufacturers can use to cut costs, boost energy density, and simplify assembly. With an eye toward the future, LEAD Intelligent is making battery manufacturing smarter and more integrated by focusing on CTP, CTC, CTB, and intelligent vehicle systems.

Integrated Solutions Across the Entire Vehicle Ecosystem

LEAD intelligent not only focuses on cell to pack battery production, but also supports intelligent motorization, cockpit systems, vehicle body assembly, and intelligent drive technology. Their comprehensive approach includes automated fluid filling, testing, and precision assembly for related components—ensuring compatibility across the vehicle powertrain and energy system.

CTP, CTC, CTB: Enabling Flexible Battery Designs

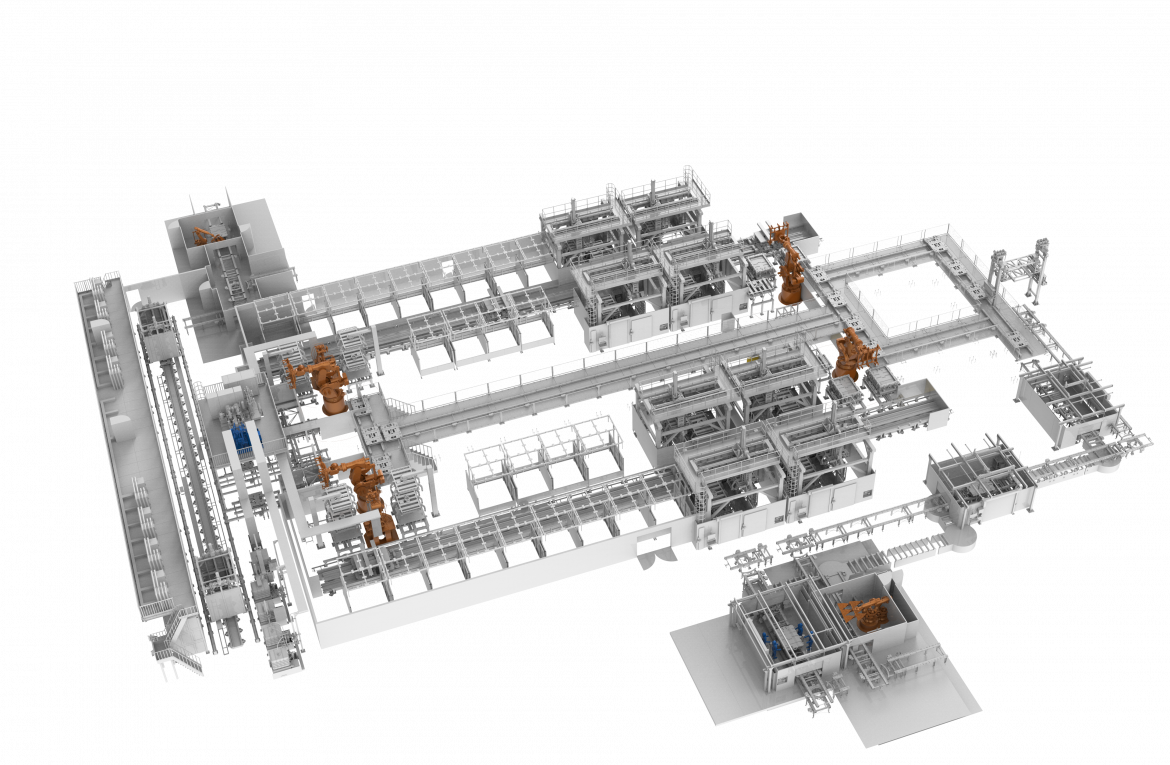

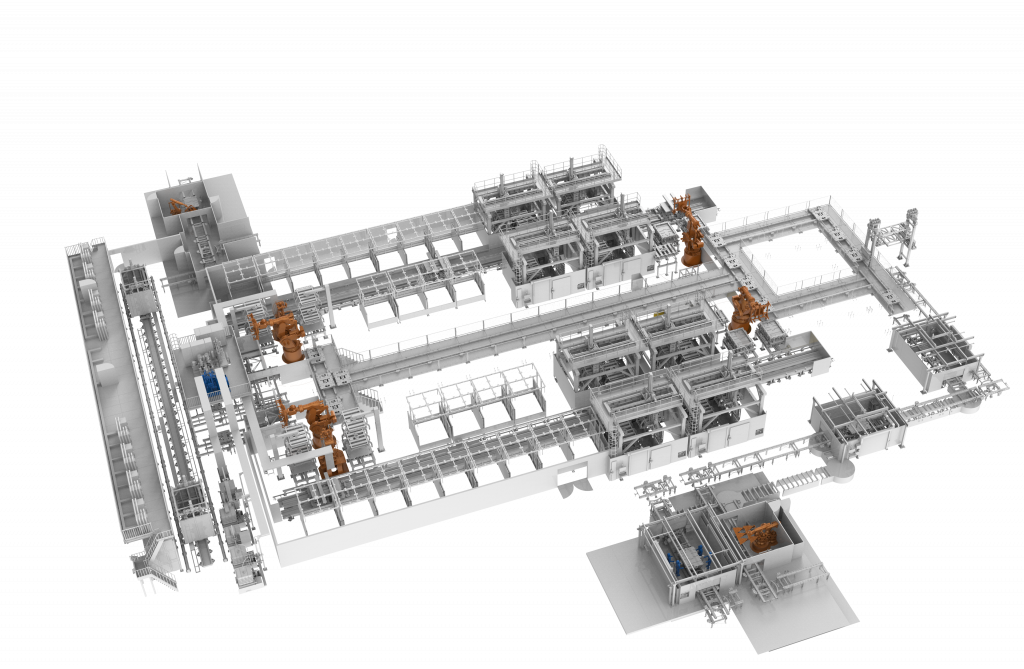

The rise of CTP (Cell to Pack), CTC (Cell to Chassis), and CTB (Cell to Body) requires production lines with higher adaptability and smarter control. LEAD Intelligent’s flexible equipment and digital automation systems allow seamless integration of varying battery pack designs—making cell to pack battery production faster, more reliable, and future-ready.

Automation Meets High Precision

From high-speed assembly to testing and data integration, LEAD Intelligent ensures every step of cell to pack battery production is tightly controlled. Their intelligent systems boost yield, improve traceability, and reduce manual error across the battery production lifecycle.

Conclusion

Supporting global EV makers in attaining scalable, smart cell to pack battery production, LEAD Intelligent provides fully integrated, forward-compatible manufacturing lines. These lines will fuel the next generation of electric transportation.